-

soldadora de la malla de la cerca

-

máquina soldada con autógena de la malla de alambre

-

soldadora automática de la malla

-

refuerzo de la soldadora de la malla

-

máquina de la malla del gabion

-

Malla de la cesta de Gabion

-

Alambre Mesh Machines

-

máquina del alambre de púas de la maquinilla de afeitar

-

Máquina ampliada del metal

-

Máquina del trefilado

-

máquina perforada del metal

-

SR. Gurami Gureshidzecaramelo mi buen amigo, proveedor honesto.

SR. Gurami Gureshidzecaramelo mi buen amigo, proveedor honesto. -

SR. MIKOUSTED ES BUENO AHORA Y SU CARAMELO ESTABLE DEL NEGOCIO.

SR. MIKOUSTED ES BUENO AHORA Y SU CARAMELO ESTABLE DEL NEGOCIO.

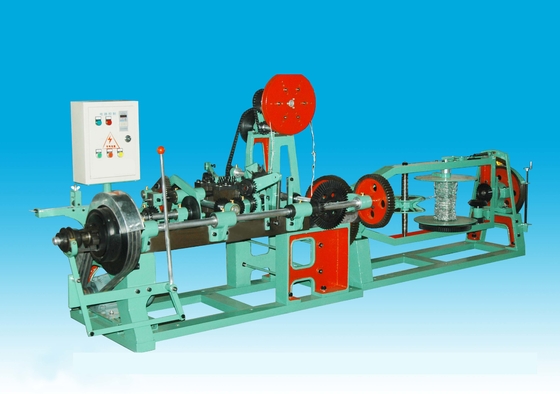

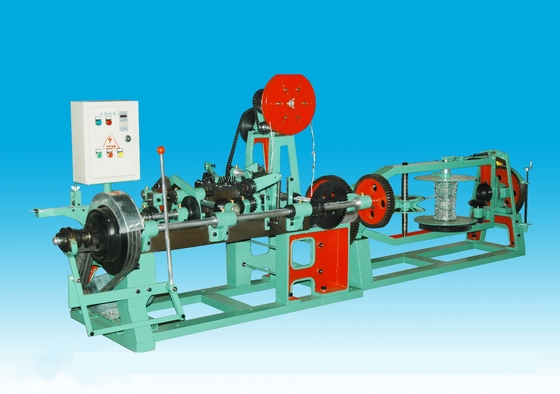

3-5 Twist Barbed Wire Machine Convenient Operation Electronic Counting Control

| Lugar de origen | Hebei, China |

|---|---|

| Nombre de la marca | DIAOZHUO |

| Certificación | CE ISO9001 |

| Número de modelo | DZ-CSA DZ-SCB DA-CSC |

| Cantidad de orden mínima | 1set |

| Precio | variable |

| Detalles de empaquetado | woodencase y las bolsas de plástico |

| Tiempo de entrega | 20-30 días |

| Condiciones de pago | L/C, D/P, T/T, Western Union, MoneyGram |

| Capacidad de la fuente | 20 sistemas por mes |

Éntreme en contacto con gratis las muestras y los vales.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

x| ingeniero | mantenga la maquinaria de ultramar | torsión | Solo |

|---|---|---|---|

| Material | alambre galvanizado caliente | Diámetro de alambre | 2.2-3m m |

| capcity | 40kg/hour | Motor | 2.2Kw |

| Resaltar | expanded metal sheet making machine,high speed expanded metal machine |

||

Convenient Operation Electronic Counting Control 3-5 Twist Barbed Wire Machine

The strands are fed intermittently by a fixed-length wire feeding mechanism. The eccentric distance on the eccentric disc can be adjusted to achieve your desired stab distance according to user requirements. The stab distance specifications are 50, 80, 100 (mm) (special specifications can be negotiated. Do), enter the winding head through the squashing device. The fan-shaped gear drives the gear shaft to return around the wire head, rotate counterclockwise, and wind the barbed wire regularly on the flattened strand position. After one round of rotation, the cam pushes the lever to raise the movable knife holder and cut the barbed wire. The stabbing action ends. The single-stranded barbed wire passes under the sliding gear, on the gliding wheel, on the wire discharging wheel, and on the take-up mandrel. The take-up sprocket is driven by the main drive sprocket to take up the wire in parallel through friction transmission.

Barbed wire is made of electric galvanized barbed wire wrapped around the main wire and twisted to protect and isolate it. The twisting method is divided into single twisting and double twisting. The construction methods include direct installation method and spiral cross method. Uses: for industrial, agricultural, animal husbandry, highway, forest farm protection.

Technical parameter of barbed wire making machine

![]()